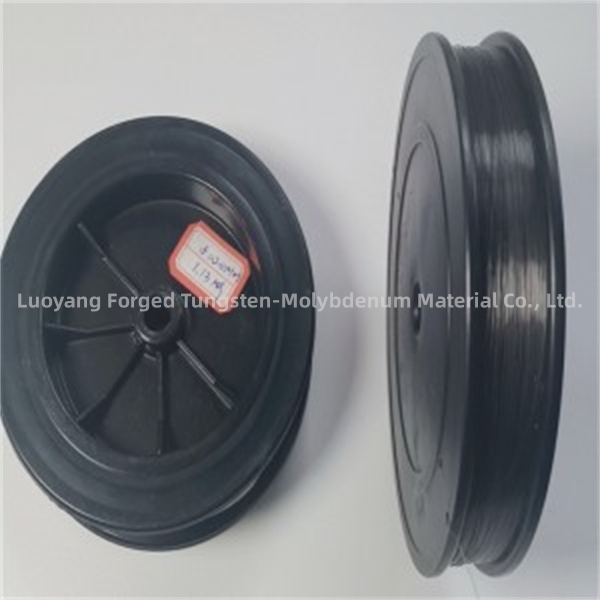

Tantalum Wire Black Customization For Electronic Industry

Tantalum is a good conductor of electricity and is known for its excellent conductivity. It has the fourth highest resistivity of all elements, behind carbon, bismuth and mercury. Tantalum's high electrical conductivity makes it valuable for a variety of electrical and electronic applications, including capacitors, high-power resistors and other components requiring reliable electrical performance. In addition, tantalum's ability to form stable oxide layers makes it particularly suitable for use as a dielectric material in capacitors.

Tantalum wire is used in a variety of applications due to its unique properties. Some common uses for tantalum wire include:

1. Capacitor: Tantalum wire is used to produce tantalum capacitors. Tantalum capacitors are widely used in electronic equipment due to their high capacitance, stability and reliability. Tantalum capacitors are commonly found in electronic devices such as smartphones, computers and medical equipment.

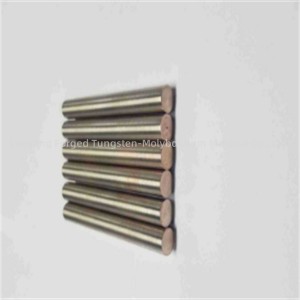

2. High-temperature furnace components: The high melting point and corrosion resistance of tantalum wire make it suitable for use in high-temperature furnace components, such as heating elements and thermocouples.

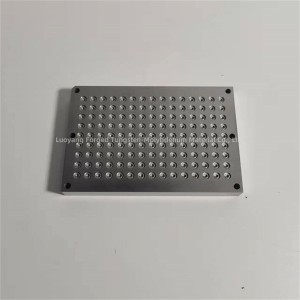

3. Chemical processing equipment: Tantalum wire is used in the construction of chemical processing equipment, especially applications involving corrosive environments or high temperatures. Tantalum's corrosion resistance makes it valuable for handling corrosive chemicals.

4. Aerospace and Defense Applications: Tantalum wire is used in aerospace and defense applications due to its high strength, heat resistance and reliability in harsh environments.

5. Medical devices: Tantalum wire is used in the production of medical devices such as implants and surgical instruments due to its biocompatibility and corrosion resistance.

Overall, tantalum wire is valued for its high melting point, excellent corrosion resistance, and good electrical conductivity, making it suitable for a wide range of critical applications across various industries.

Tantalum is not typically used as an insulator. In fact, tantalum is known for its excellent electrical conductivity and is often used in electronic components such as capacitors due to its ability to form stable oxide layers (used as dielectrics in capacitors). Tantalum's high conductivity and other properties make it valuable for a variety of electrical and electronic applications, but it is not commonly used as an insulator.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com