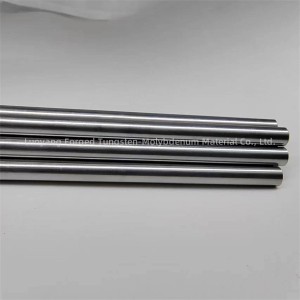

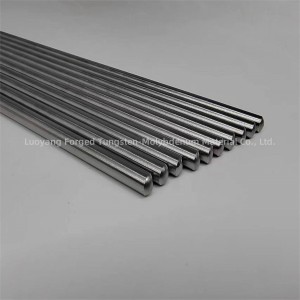

99.95% wolfram tube pure tungsten pipe for heating elements

Thermocouple protection tube is a tube or jacket designed to enclose and protect thermocouple sensors from harsh operating environments. These tubes are usually made of materials that can withstand high temperatures, corrosion and mechanical stress, ensuring accurate and reliable measurement of temperature in industrial processes. Protective tubes protect delicate thermocouple elements from direct contact with the process environment, allowing them to function effectively and extending their service life. Materials such as ceramics, metal alloys, and refractory metals such as tungsten are commonly used to make thermocouple protection tubes.

Thermocouples can be protected in a variety of ways to ensure their accuracy and longevity in harsh operating conditions:

1. Use a protective tube: As mentioned earlier, thermocouple protective tubes made of materials such as ceramics, metal alloys, or refractory metals like tungsten can protect thermocouple sensors from extreme temperatures, chemical corrosion, and mechanical damage.

2. Use a sheath: Encasing a thermocouple in a protective metal or ceramic tube prevents direct contact with the process environment, extending its life and maintaining accurate temperature measurements.

3. Select the appropriate material: According to the specific working conditions, such as high temperature, corrosive atmosphere or abrasive environment, selecting the appropriate thermocouple sheath or protective tube material is crucial for effective protection.

4. Regular maintenance: Regular inspection, cleaning, and calibration of thermocouples help ensure their continued accuracy and performance.

By implementing these protective measures, thermocouples can maintain their functionality and accuracy in demanding industrial environments.

Yes, thermocouples should be shielded in many industrial applications to protect them from harsh operating conditions. Shielding a thermocouple with a protective tube or sheath made of suitable materials can help maintain its accuracy and extend its service life in high temperature, corrosive or abrasive environments. Shielding helps ensure reliable temperature measurements and prevent premature thermocouple failure by providing a barrier between the thermocouple sensor and the process environment.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com