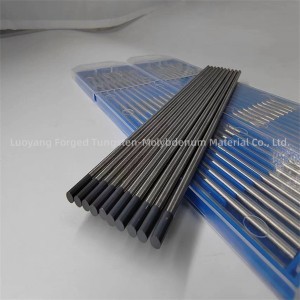

WC20 Gray head tungsten needle tungsten rod cerium tungsten electrode

The production methods of WC20 tungsten electrodes, grey-tipped tungsten needles, tungsten rods and cerium tungsten electrodes can vary depending on the specific type of electrode and its intended use. However, I can give you a general overview of how tungsten electrodes and tungsten rods are produced:

1. Tungsten powder production: The production process usually starts with the production of tungsten powder. Tungsten oxide is reduced to tungsten powder through a chemical process, and the resulting powder is then consolidated through sintering to form a solid tungsten rod or electrode.

2. Additive incorporation: For electrodes such as WC20 and cerium tungsten electrodes, tungsten powder is mixed with specific additives (such as cerium oxide for cerium electrodes) to obtain the desired performance. The powder mixture is then pressed and sintered to form the electrode body.

3. Electrode shaping: The sintered tungsten rod is further processed to form a specific electrode shape. This may involve grinding, machining or forming the electrode into the desired structure, such as the tip of a tungsten needle or a specific head design for a ceramic electrode.

4. Quality Control: Throughout the entire production process, quality control measures are implemented to ensure that electrodes meet required composition, size and performance characteristics specifications. Non-destructive testing methods can be used to verify electrode integrity.

5. Surface treatment: Depending on the application, electrodes can be surface treated, such as ground, polished or coated, to obtain the desired surface properties and appearance.

The production of tungsten electrodes and rods involves precision manufacturing processes and may require specialized equipment and expertise due to the unique properties of tungsten. Additionally, due to the potential health hazards associated with tungsten powder, safety measures should be taken when handling tungsten materials, especially in powdered form.

Each type of tungsten electrode you mentioned has specific applications based on its properties and composition. The following are typical applications for each type:

1. WC20 tungsten electrode: WC20 electrode contains 2% cerium oxide and is commonly used for TIG (tungsten inert gas) welding of non-ferrous metals such as aluminum and magnesium. The addition of cerium oxide enhances arc initiation and stability, making WC20 electrodes suitable for both AC and DC welding applications.

2. Gray-tipped tungsten needles: Tungsten needles, especially those with fine and precise tips, are used in micro-welding applications, precision welding, and situations where a concentrated and controlled arc is required. These needles are typically used for welding thin materials and applications that require small, precise welds.

3. Tungsten rod: Whether it is pure tungsten or tungsten alloy, tungsten rod has a wide range of uses. They are used as electrodes in gas tungsten arc welding (GTAW or TIG welding), heating elements in high-temperature furnaces, electrical contacts in various equipment, and as raw materials in the manufacture of other tungsten products.

4. Cerium-tungsten electrode: Cerium-tungsten electrode is similar to WC20 electrode and is used for TIG welding of non-ferrous metals and alloys. The addition of cerium oxide enhances arc initiation and stability, making these electrodes suitable for applications requiring a stable arc.

Each type of tungsten electrode has specific properties that make it suitable for specific welding applications, depending on factors such as the type of material to be welded, the welding current and the required arc characteristics.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com