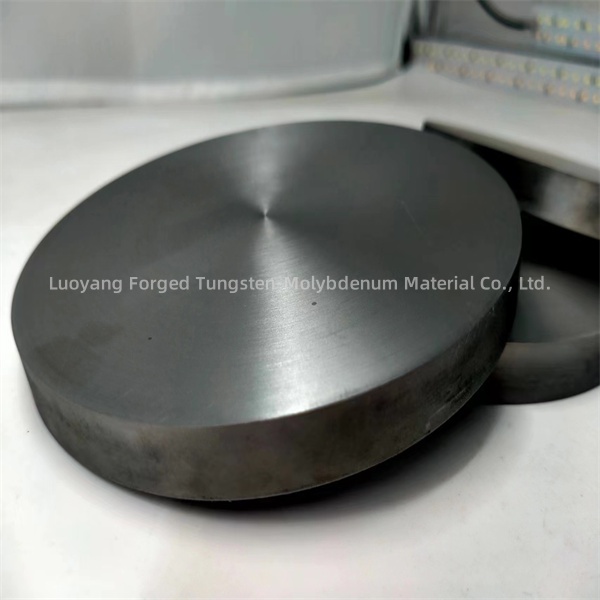

High purity titanium sputtering target for vacuum coating

Sputter targets are high-purity materials used in physical vapor deposition (PVD) processes, specifically sputtering technology. These materials are used to form thin films on substrates in a variety of industries, including semiconductor manufacturing, optical coatings, and thin film deposition for electronic devices.

Sputter target materials can be made from a variety of elements and compounds, including metals, alloys, oxides and nitrides. The choice of sputter target material depends on the specific properties required for the thin film coating, such as electrical conductivity, optical properties, hardness and chemical resistance.

Common sputtering targets include metals such as titanium, aluminum and copper, as well as compounds such as indium tin oxide (ITO) and various metal oxides. Selecting the appropriate sputtering target material is critical to achieving the desired characteristics and performance of thin film coatings.

Sputtering targets come in various sizes depending on the specific requirements of the thin film deposition process and sputtering equipment. The size of the sputtering target can range from a few centimeters to tens of centimeters in diameter, and the thickness can also vary.

The size of the sputtering target is determined by factors such as the size of the substrate to be coated, the configuration of the sputtering system, and the desired deposition rate and uniformity. Additionally, the size of the sputtering target may be affected by the specific requirements of the thin film application, such as the area to be coated and overall process parameters.

Ultimately, the size of the sputter target is selected to ensure efficient and uniform deposition of the film onto the substrate, meeting the specific needs of the thin film coating process in semiconductor manufacturing, optical coatings and other related applications.

There are several ways to increase the sputtering rate in a sputtering process:

1. Power and Pressure Optimization: Adjusting the power and pressure parameters in the sputtering system can impact the sputtering rate. Increasing the power and optimizing the pressure conditions can enhance the sputtering rate, leading to faster deposition of the thin film.

2. Target Material and Geometry: Using sputtering targets with optimized material composition and geometry can improve the sputtering rate. High-quality, well-designed sputtering targets can enhance the sputtering efficiency and lead to higher deposition rates.

3. Target Surface Preparation: Proper cleaning and conditioning of the sputtering target surface can contribute to increased sputtering rates. Ensuring the target surface is free from contaminants and oxides can improve the sputtering efficiency.

4. Substrate Temperature: Controlling the substrate temperature can impact the sputtering rate. In some cases, raising the substrate temperature within a certain range can lead to increased sputtering rates and improved film quality.

5. Gas Flow and Composition: Optimizing the gas flow and composition in the sputtering chamber can affect the sputtering rate. Adjusting the gas flow rates and using the appropriate sputtering gas mixtures can enhance the sputtering process efficiency.

By carefully considering these factors and optimizing the sputtering process parameters, it is possible to increase the sputtering rate and improve the overall efficiency of thin film deposition in sputtering applications.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com