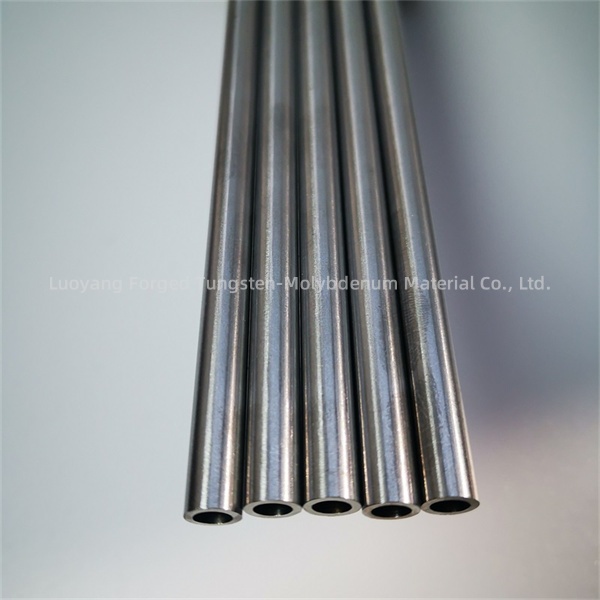

Titanium tube for thermocouple protection tube

The terms "thermowell" and "protection tube" are commonly used in industrial temperature measurement and control. Although their uses are similar, there are some differences between the two:

Thermowell:

A thermowell is a closed-end tube installed in a process vessel or pipe to protect a temperature sensor, such as a thermocouple or resistance temperature detector (RTD), from the process fluid. Thermowells allow temperature sensors to be inserted into the process while providing a barrier that protects the sensor from corrosive, abrasive, or high-pressure conditions of the process fluid. Thermowells are designed to isolate the temperature sensor from the process environment while allowing accurate temperature measurement.

Protective tube:

A protective tube, on the other hand, is a tube or sheath that serves a similar purpose to a thermowell. It is used to protect temperature sensors from harsh process conditions, such as high temperatures, corrosive atmospheres or abrasives. Protective tubes are typically used in applications where direct exposure of the temperature sensor to the process environment may result in sensor damage or inaccurate temperature readings.

To summarize, while both thermowells and protective tubes are used to protect temperature sensors, thermowells are usually designed with closed ends and installed in containers or pipes, while protective tubes are more versatile and can be used in a variety of applications. Configured to shield the temperature sensor from harsh environments.

When selecting a thermocouple type, several factors should be considered to ensure it is suitable for a specific application:

1. Temperature range: Determine the temperature range of the application. Different thermocouple types have different temperature limits, so choose a type that can accurately measure the expected temperature range.

2. Accuracy requirements: Consider the accuracy required for temperature measurement. Some thermocouple types provide greater accuracy than others, especially within specific temperature ranges.

3. Environmental conditions: Assess environmental conditions, including the presence of corrosive substances, vibration and pressure. Select a thermocouple type that can withstand the environmental factors present in the application.

4. Response time: Consider the response time required for temperature measurement. Some thermocouple types have faster response times than others.

5. Cost: Evaluate the cost of the thermocouple type and consider the application’s budget.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com