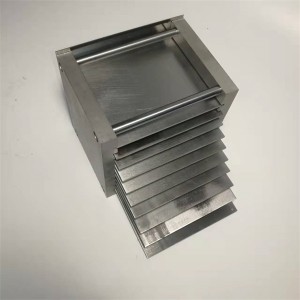

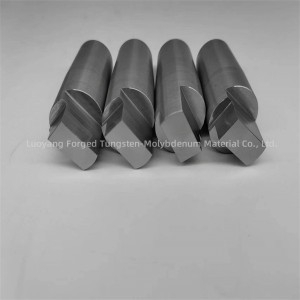

the high melting pointing molybdenum pin for steel melting

Several elements are known for their high melting points, which makes them valuable for a variety of industrial, scientific, and technological applications. Some elements with extremely high melting points include:

1. Tungsten: Tungsten has the highest melting point of all metals, approximately 3,422 degrees Celsius (6,192 degrees Fahrenheit). This special melting point makes tungsten very valuable in high temperature applications such as the aerospace industry, electrical contacts and high temperature furnaces.

2. Rhenium: Rhenium has the third highest melting point of all elements, about 3,180 degrees Celsius (5,756 degrees Fahrenheit). Rhenium's high melting point and resistance to wear and corrosion allow it to be used in high-temperature applications, including superalloys for aerospace and industrial gas turbine engines.

3. Osmium: Osmium has a melting point of approximately 3,033 degrees Celsius (5,491 degrees Fahrenheit), making it one of the elements with a very high melting point. Osmium is used in certain high-temperature alloys and in special applications requiring extremely high hardness and corrosion resistance.

4. Tantalum: Tantalum has a high melting point of approximately 3,020 degrees Celsius (5,468 degrees Fahrenheit). Tantalum's high melting point and excellent corrosion resistance make it valuable in chemical processing equipment, high-temperature furnace components, and electronic components.

5. Molybdenum: Molybdenum has a high melting point, approximately 2,623 degrees Celsius (4,753 degrees Fahrenheit). Molybdenum's high melting point and its excellent thermal conductivity and strength at high temperatures make it valuable for a variety of high-temperature applications, including aerospace, defense and industrial processes.

These elements are valued for their high melting points, which allow them to maintain structural integrity and performance in extreme temperatures. Their unique properties make them critical for applications where the material is subject to high heat and thermal stress.

The melting point of a substance is affected by a variety of factors, including intermolecular forces, molecular structure, and external pressure. Here are some key factors that influence the melting point of a substance:

1. Intermolecular force: The strength of intermolecular force between molecules has a great influence on the melting point. Substances with strong intermolecular forces, such as ionic or covalent bonds, generally have higher melting points. For example, metal and ionic compounds tend to have high melting points due to the strength of their bonding forces.

2. Molecular size and shape: The size and shape of the molecule affects the melting point. Larger molecules with more complex structures generally have higher melting points due to increased surface area and stronger intermolecular interactions. Conversely, smaller, more spherical molecules may have lower melting points.

3. Polarity: Polar molecules have uneven charge distribution and tend to have higher melting points than non-polar molecules. This is because polar molecules exhibit stronger intermolecular attractions, such as dipole-dipole interactions and hydrogen bonding.

4. Crystal structure: The arrangement of particles in a solid crystal lattice affects the melting point. Substances with well-ordered and closely packed crystal structures generally have higher melting points than those with less organized structures.

5. Pressure: In some cases, the melting point of a substance is affected by external pressure. For example, increasing pressure can raise the melting point of certain substances, especially those that exhibit unusual behavior at high pressures.

6. Impurities: The presence of impurities in a substance lowers its melting point. Impurities disrupt the regular lattice structure, making it easier for substances to transition from solid to liquid.

7. Isotope composition: Isotope composition, especially the isotopic composition of elements, can affect the melting point. Isotopes with different atomic masses may exhibit slightly different melting points due to their different atomic interactions.

Understanding these factors is critical to predicting and explaining the melting behavior of different substances. By considering the interaction of these factors, scientists and engineers can gain insights into the physical properties of materials and how they behave under different conditions.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com