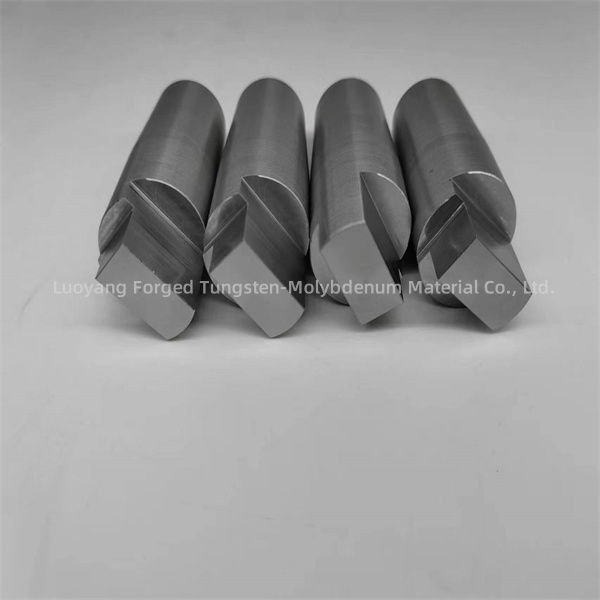

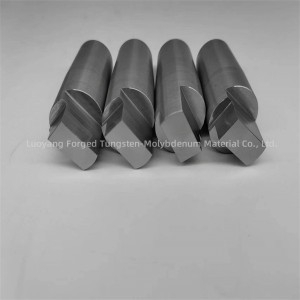

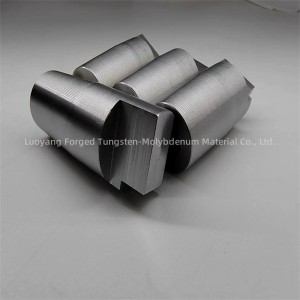

TZM alloy polished electrode rod used in the semiconductor industry

TZM alloy is a high-performance material alloyed with molybdenum (Mo), titanium (Ti) and zirconium (Zr). The acronym "TZM" is derived from the first letters of the elements in the alloy. This combination of elements gives the material excellent high-temperature strength, good thermal conductivity and resistance to thermal creep, making it suitable for demanding applications in industries such as aerospace, defense, electronics and high-temperature processing.

TZM alloys are known for their ability to maintain mechanical properties at high temperatures, making them valuable for critical applications that require stability and performance under extreme conditions.

The recrystallization temperature of TZM (Titanium Zirconium Molybdenum) alloy is approximately 1300°C to 1400°C (2372°F to 2552°F). Within this temperature range, deformed grains in the material recrystallize, forming new unstrained grains and eliminating residual stresses. Understanding the recrystallization temperature is important for processes such as annealing and heat treatment, where the microstructure and mechanical properties of the material are optimized for specific applications.

TZM alloys are composed of titanium (Ti), zirconium (Zr) and molybdenum (Mo) and are used in a variety of high-temperature applications due to their excellent mechanical and thermal properties. Some common uses of TZM alloys include:

1. Aerospace and Defense: TZM is used in aerospace and defense applications for components requiring high-temperature strength and stability, such as rocket nozzles, high-temperature structural parts and other critical components.

2. High-temperature furnace components: TZM is used in the construction of high-temperature furnaces in metallurgy, glass manufacturing, semiconductor processing and other industries. Its high-temperature strength and thermal stability are crucial.

3. Electrical and electronic components: TZM is used in electrical contacts, heat sinks and other electronic components due to its good electrical conductivity and thermal properties.

4. Medical equipment: TZM is used in medical equipment and devices, especially applications that require high temperature resistance and biocompatibility, such as X-ray tubes and radiation shielding.

Overall, TZM alloys are valued for their ability to withstand high temperatures, provide excellent thermal and mechanical properties, and maintain stability in harsh environments, making them suitable for a variety of critical applications.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com