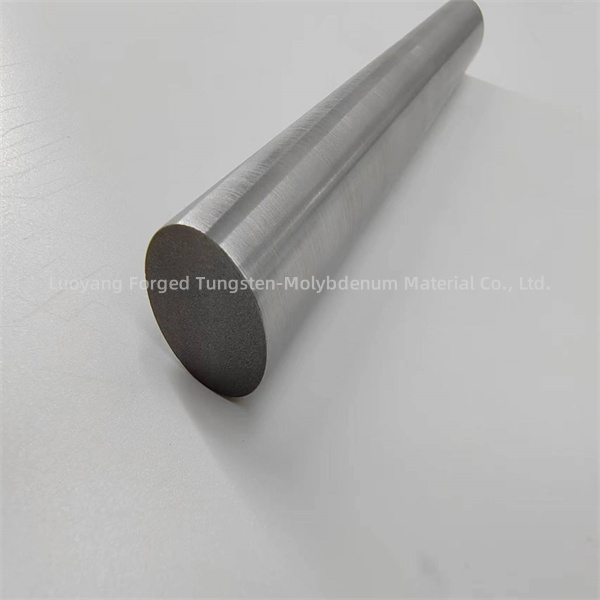

WLa Tungsten Lanthanum Alloy Rod With Polished Surface

We no longer use thorium tungsten due to health and safety concerns associated with the radioactive element thorium. Thorized tungsten electrodes are commonly used in welding applications, especially TIG (tungsten inert gas) welding, due to their ability to maintain a stable arc and provide good performance at high temperatures. However, thorium is a radioactive substance and inhaling thorium dust or fumes produced during welding can pose health risks, particularly to the lungs. As a result, there is a shift toward non-radioactive alternatives such as cerium, lanthanum, or zirconium tungsten electrodes, which have comparable performance to thorium tungsten but without the associated health hazards. This shift is consistent with efforts to prioritize worker safety and minimize exposure to hazardous substances in industrial settings.

The best tungsten for TIG (tungsten inert gas) welding of stainless steel is usually thoriated tungsten. However, due to the health and safety concerns associated with thoriated tungsten, non-radioactive tungsten alloys such as cerium tungsten, rare earth tungsten or zirconium tungsten are often used as alternatives. These tungsten alloys offer good arc stability, low electrode consumption, and excellent performance at both low and high currents, making them suitable for TIG welding of stainless steel and other materials. When choosing the best tungsten for TIG welding of stainless steel, it is important to consider factors such as the specific grade of stainless steel, welding parameters and required welding properties to ensure the best results.

The best tungsten rod for TIG (tungsten inert gas) welding depends on the specific requirements of the welding application. Non-radioactive tungsten alloys, such as tungsten cerium, tungsten lanthanate or tungsten zirconium, are commonly used in TIG welding due to their excellent performance properties. Cerium tungsten is known for its good arc stability and is commonly used to weld steel, stainless steel and nickel alloys. Tungsten lanthanide has similar properties and is suitable for both AC and DC welding applications. Zirconium tungsten is valued for its ability to resist contamination and is commonly used for welding aluminum and magnesium alloys. When choosing the best tungsten rod for TIG welding, it is important to consider the specific material to be welded, the welding process and the required welding performance to ensure the best results.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com