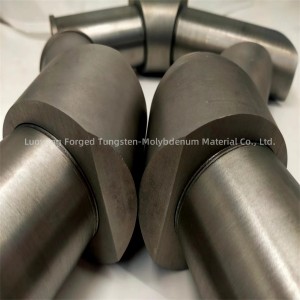

Molybdenum Tungsten Alloy Pipe Molybdenum Alloy Tube for Sale

Molybdenum-tungsten alloy, also known as molybdenum-tungsten alloy (Mo-W), is a composite material combining molybdenum and tungsten. The alloy is made by mixing molybdenum and tungsten powders and then sintering them at high temperatures to form a solid material that combines the properties of both elements.

Molybdenum-tungsten alloys are valued for their high-temperature strength, excellent thermal conductivity, and thermal creep resistance. These properties make them suitable for use in high-temperature applications such as aerospace components, electrical contacts, and high-temperature furnace components.

The specific composition of molybdenum-tungsten alloys can be tailored to achieve the desired properties, making them a versatile material suitable for a variety of industrial and technical applications that require a combination of the properties of molybdenum and tungsten.

Molybdenum and tungsten are both refractory metals with high melting points and excellent mechanical and thermal properties, but they have some significant differences:

1. Melting point: The melting point of tungsten is higher than that of molybdenum. Tungsten has the highest melting point at 3422°C, while molybdenum has a melting point of 2623°C.

2. Density: Tungsten is denser than molybdenum. Tungsten has a density of 19.25 g/cm3, while molybdenum has a density of 10.28 g/cm3.

3. Mechanical properties: Tungsten is harder and brittle than molybdenum. Tungsten is commonly used in applications where hardness and wear resistance are critical, such as cutting tools and high-temperature furnace components. Molybdenum, on the other hand, is more ductile and is often used in applications where toughness and flexibility are important.

4. Applications: Due to its high melting point and hardness, tungsten is commonly used in high-temperature applications such as the aerospace industry, electrical contacts, and as a material for light bulb filaments. Molybdenum is also used in high-temperature applications, but is typically chosen for its ability to withstand thermal shock and its excellent thermal conductivity.

In summary, while molybdenum and tungsten are both valuable materials with similar properties, their differences in melting point, density, mechanical properties and applications make them suitable for different industrial and technical uses.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com