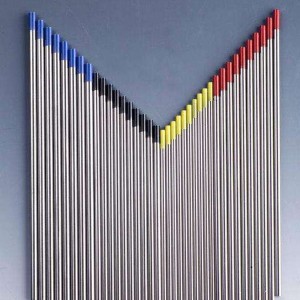

Black Forged Glass Melting Furnace Molybdenum Electrodes

Furnaces are typically constructed using several metals, each chosen for its specific properties and suitability for high-temperature applications. Some of the metals used in furnaces include:

1. Steel: Steel is a widely used material in furnace construction due to its strength, durability and relatively low cost. Carbon and stainless steel are commonly used for furnace shells, structural components and support structures.

2. Refractory metals: Refractory metals such as molybdenum, tungsten, tantalum and niobium are used in high temperature furnace applications due to their high melting point, strength at high temperatures, heat resistance and corrosion resistance. These metals are commonly used in heating elements, furnace components, and fixtures.

3. Nickel-based alloys: Nickel-based high-temperature alloys are used for furnace components exposed to high temperatures and corrosive environments. These alloys offer high-temperature strength, oxidation resistance, and thermal stability, making them suitable for heat treatment and high-temperature processing applications.

4. Copper and copper alloys: Copper and its alloys, such as brass and bronze, are used in certain furnace components, especially in applications that require good thermal and electrical conductivity. Copper is commonly used in furnace coils and electrical connections.

5. Cast Iron: Cast iron is used in certain types of furnaces, particularly in applications where its thermal conductivity and resistance to thermal shock are beneficial. It is commonly used in the construction of certain types of industrial furnaces and stoves.

The selection of metals for furnace construction depends on a variety of factors, such as operating temperature, the type of atmosphere in the furnace, the specific application of the furnace, and considerations related to cost and availability. Each metal has specific advantages and limitations, and the choice of material depends on the specific requirements of the furnace and the intended application.

Glass is usually melted in a furnace called a "glass furnace" or "glass melting furnace". There are many types of glass furnaces, each designed for a specific glass production process. Some common types of glass furnaces include:

1. Retort Furnaces: Retort furnaces are small traditional furnaces used for melting small quantities of glass. They are often used in artisanal or small-scale glassblowing operations.

2. Retort Furnace: Retort furnace is a large continuous furnace used for large-scale production of glass. They are commonly used in the production of container glass, flat glass and fiberglass. Tank furnaces are designed to hold large quantities of molten glass and are capable of continuous operation.

3. Daily Retort Furnace: Daily retort furnace is a smaller version of the retort furnace and is used in smaller-scale glass production, such as the production of specialty glasses or in R&D environments.

4. Tank-type arch furnace: Tank-type arch furnace is used to produce optical glass, special fibers and other special glasses. They are designed to provide precise control of the melting process to achieve specific glass compositions and properties.

These furnaces use a variety of heating methods, including resistance heating, combustion heating and induction heating, depending on the specific requirements of the glass production process. Furnace selection depends on factors such as the type of glass being produced, throughput, energy efficiency considerations, and the specific requirements of the glass manufacturing process.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com