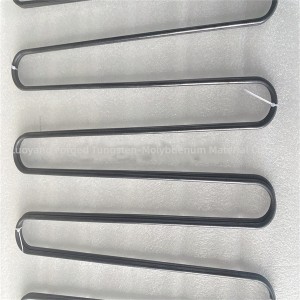

Customized 99.95% Pure Molybdenum Boat Thermal Evaporation

The evaporation temperature (also called the boiling point) of a substance can be calculated using various methods, depending on the available data and the specific properties of the substance. Here are a few common ways to calculate evaporation temperature:

1. Use chemical data: The evaporation temperature of a substance can usually be found in chemical databases or literature. Many substances have well-documented boiling points at standard pressure (1 atmosphere). This is the simplest and most accurate way to determine evaporation temperature if data are available.

2. Use the Clausius-Clapeyron equation: The Clausius-Clapeyron equation can be used to estimate the change in vapor pressure of a substance as a function of temperature. By plotting the natural logarithm of vapor pressure against the reciprocal of temperature, the slope of the resulting line can be used to calculate the enthalpy of vaporization, which in turn can be used to estimate the boiling point at different pressures.

3. Use vapor pressure data: If vapor pressure data for a substance at different temperatures are available, you can use Antoine's equation or other empirical equations to fit the data and infer the boiling point at standard pressure.

4. Use molecular dynamics simulations: For complex substances or when experimental data are limited, molecular dynamics simulations can be used to calculate the evaporation temperature based on the behavior of individual molecules and their interactions.

It is important to note that the accuracy of the calculated evaporation temperature depends on the quality of the data and the method used. When handling hazardous materials, it is crucial to consult reliable sources and ensure safety precautions are followed.

The three conditions most suitable for evaporation are:

1. High temperature: Evaporation occurs faster at higher temperatures because the increased heat energy provides the molecules with greater kinetic energy, allowing them to overcome intermolecular forces and escape from the liquid phase to the gas phase.

2. Low humidity: The ambient air humidity is low and the vapor pressure difference between the liquid and the air is large, which is conducive to faster evaporation. When the air is saturated with water vapor (high humidity), the evaporation rate decreases because the concentration gradient of water molecules moving from the liquid phase to the gas phase decreases.

3. Increased surface area: The greater surface area of a liquid exposed to surrounding air promotes faster evaporation. This is why, for example, wet clothes dry faster when they are spread out rather than clumped together, because the increased surface area allows more water molecules to escape into the air.

Together, these conditions help increase the rate of evaporation, allowing substances to transition from liquid to gas phase more efficiently.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com